Discharge ink is a bleaching type of ink that creates a bright, no feel print on cotton t-shirts.

Discharge t-shirt printing can produce some really excellent results, however there are some risks, and some complications that should be considered. First off, let’s explain exactly what is happening with discharge ink:

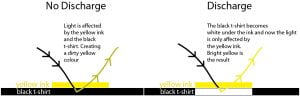

Discharge is a chemical that we mix into a water base carrier (such as water base ink) that when heated up, reacts with the dye in the t-shirt rendering it inert. This “bleaching” effect happens in the conveyor dryer after the ink is applied to the t-shirt and only in the places where ink touches t-shirt. The result is that the colour of the shirt under the print effectively disappears and the fabric reverts back to the colour of cotton. Since the discharge ink also contains a pigment colour, what appears to happen is that the print goes into the dryer looking dull and sometimes barely visible, but appears to brighten and “pop’ as it heats up.

It is a pretty exciting way to print because the image exits the dryer looking very different than it went in.

We can achieve some pretty great results with discharge printing, the greatest benefit being that ink can be printed very thin on dark garments and therefor have no feel to your hand. However, due to the fact that it is a chemical reaction, there are many variables that need to be considered, so let’s talk about what can go wrong:

Here are the list of things to be aware of when printing discharge ink:

First off, discharge only works on reactive dyes, which in most cases will restrict you to 100% cotton fabrics. Polyester fabrics and tri-blends are not usually dyed with reactive dyes, and so they do not discharge. This isn’t always the case, so read the ‘best decorating options’ at the bottom of each page on the getbold website to know if the t-shirt you are looking at can be discharged. More expensive cotton/poly blends can sometimes be discharged.

Also, certain colours of t-shirts, even when using 100% cotton, can be difficult to discharge. Be careful with colours such as royal blue, kelly green, or light purple. These tend to only half discharge.

Another thing to keep in mind is that different dye lots can discharge differently. So it is not uncommon for the mediums to look different from the smalls – they will still look good, just different.

Lastly, sometimes things just go wonky. Once we were discharging a black shirt with orange ink and the ink came out of the dryer a dirty brown – pink. We never did figure out why. We had to abort the print and switch to a different printing method.

In conclusion, if a no feel bright colour print is what you are looking for, discharge ink might be your best option, but it’s complicated. We recommend you give us a call and discuss with us what t-shirt styles will work best for your project. Together we can help you make something great!

Here is a great video that Bella/Canvas made, testing multiple fabrics with discharge printing. Give it a watch, it is very informative.