Getting familiar with fabric types

When it comes to printing, one of the most important factors to consider is the fabric type you’re printing on. The initial instinct is to think about your artwork first, however, if you want that artwork to print with the best outcome you absolutely have to consider the surface you are applying it to. Think of it this way, a painter won’t just start painting on any surface, first, they’ll choose the canvas that best suits their paints to make sure they work properly together. Here we will go over the various fabric types and what print methods work best for each one.

Cotton

We will start out with one of the most common, versatile fabrics in the printing world: cotton. Cotton also happens to have many different variations that allow different capabilities.

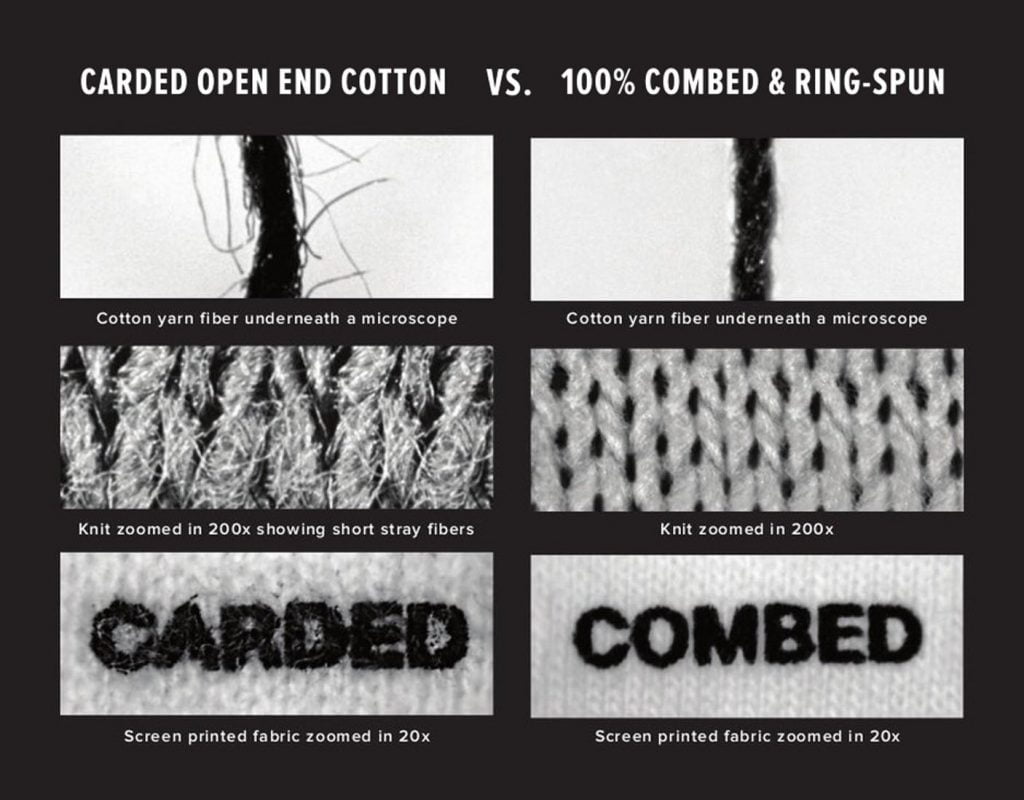

Carded open-end cotton is the standard cotton you get in all the basic t-shirts like the Gildan #2000 or Alstyle #1301. The feel of this cotton can be described sometimes as “rough” or “starchy”, this is because it’s made from fibres that are twisted together, then woven to create the fabric. This means there are odds and ends sticking out at the microscopic level which is what causes it to be on the rough side. So why is this still the industry standard for basic t-shirts? It’s more environmentally friendly to produce with less procedures and energy used than Ringspun Cotton and it’s also the cheapest method. Typically t-shirts using this type of cotton will be great for screen printing whether you need to print a single colour or multiple colours. Standard Plastisol, Plasticharge, and Waterbase Discharge inks will all work well with this type of shirt. Cotton is also great if you’re going the fancy route and want to use Metallic Ink or Foil in your design.

Softspun/Ringspun cotton is in between C.O.E. cotton and Combed Ringspun. Often referred to as “Softspun”, you’ll see this method used with brands like M&O and the Fruit of the Loom. The fibres are longer and thinner, woven together in the same direction as opposed to being twisted randomly together to create a smoother softer feel. Shirts made this way will have a slightly softer surface than C.O.E. cotton, but won’t be as durable and soft as the superior Combed Ringspun cotton which has even more impurities spun out of the yarn. This type of cotton has the same decoration capabilities as C.O.E. cotton.

Combed Ringspun cotton is the step up from regular Ringspun cotton. This is starting to become an industry standard when it comes to higher-end clothing with brands like Bella+Canvas and American Apparel only using this type of cotton. The difference between Combed Ringspun and regular Ringspun/Softspun is that the raw cotton has undergone a refining, or “combing” process that eliminates any impurities. Essentially, any extra bits of plant fibre that may still be lingering in regular Ringspun cotton is completely gone in Combed Ringspun. This creates a super soft feel, stronger fibres, smoother printing surface, and helps it hold up the t-shirt better after washing. This type of cotton works great with both Screen Printing and Direct-to-Garment printing.

Poly/Cotton Blends

Poly/cotton blends can give you the best of both worlds. T-shirts with this blend will often be quite thin and super soft. The polyester helps prevent the shirt from shrinking up in the wash and keeps it soft, and the cotton helps it print better and keeps it breathable. Anytime you see a shirt with a speckle in it, that will automatically be a poly/cotton blend. The speckle is created using plastic to create a multi-tonal shirt. These shirt colours are called “Heather” and can actually help make your design stand out in different unique ways. Poly/Cotton shirts will print best with reduced Plastisol inks. Reduced ink is created when we add a reducer to an ink colour to thin it out. We pair that with a very high screen mesh so the least amount of ink can go through the screen and this combo can create a vintage look to the print which looks even cooler when applied to a Heather shirt. The result is a thin, soft feeling print that contains some aspects of the shirt colour it’s printed on while maintaining a reduced/vintage-style look of the original design. If you’re using regular Plastisol ink without reducer added, we recommend avoiding large, thick prints with more than 3 colours because this can make a Poly/Cotton shirt very heavy to wear. Metallic inks and foil will not work with blends because of the high heat needed to apply these methods. Due to the Polyester content of these shirts, the more heat you add the more likely the shirt will burn or discolour.

Tri-blends

Tri-blends are made up of Cotton, Polyester, and Rayon. Rayon is a semi-synthetic fabric that adds extra elasticity to the garment. Tri-blends are some of the comfiest, softest fabrics you can find, however, that also means they’re the most expensive. Typically they’re on the thinner side just like poly/cotton blends which means they fit similar print diameters. We suggest using a Reduced Plastisol ink method for Tri-blend fabrics to help keep the print thin and soft on your shirt. Tri-blends can burn quite easily just as 100% Polyester fabrics do, so while Regular Plastisol ink will work as well, due to the high synthetic content of these blends it’s best to stick with 3 colours or less in your design. The same rules for Poly/Cotton shirts apply here when it comes to Metallic inks and foil.

Polyester

Polyester is essentially plastic woven together to create a fabric. This is great if you’re looking for sportswear as polyester garments often have moisture-wicking properties for sweating a lot and they have a smoother silky feel. There are however certain limitations to printing with polyester garments. Because they’re made of plastic, the higher the heat you apply, the more likely that plastic is going to burn or discolour. When you screen print, the more colours in your design, the more flashes need to be applied. A flash happens between two ink colours to help dry ink colour #1 before #2 is applied. The flash is a super hot machine that gives a burst of heat and light to help dry that ink. You can see how this would be an issue if you have multiple colours going onto plastic, the more you flash the more likely the polyester will get too hot and start to burn. If you’re printing on polyester garments, we suggest sticking with either reduced plastisol ink, or regular plastisol ink with a maximum of 3 colours in your design. Polyester will not work with metallic inks or foil methods because both these need extreme heat to be applied to the shirt. Polyester material will also not Discharge and does not work for Direct-to-Garment printing.

Overview

It seems like there’s a lot to consider when choosing the right t-shirt, but why can’t it be more simple? Well, that’s why we’re here! We can help you choose the perfect garment for your design. Never hesitate to reach out to us! Check out our Contact Us page to get a hold of us and we’ll be happy to help with any questions you have.

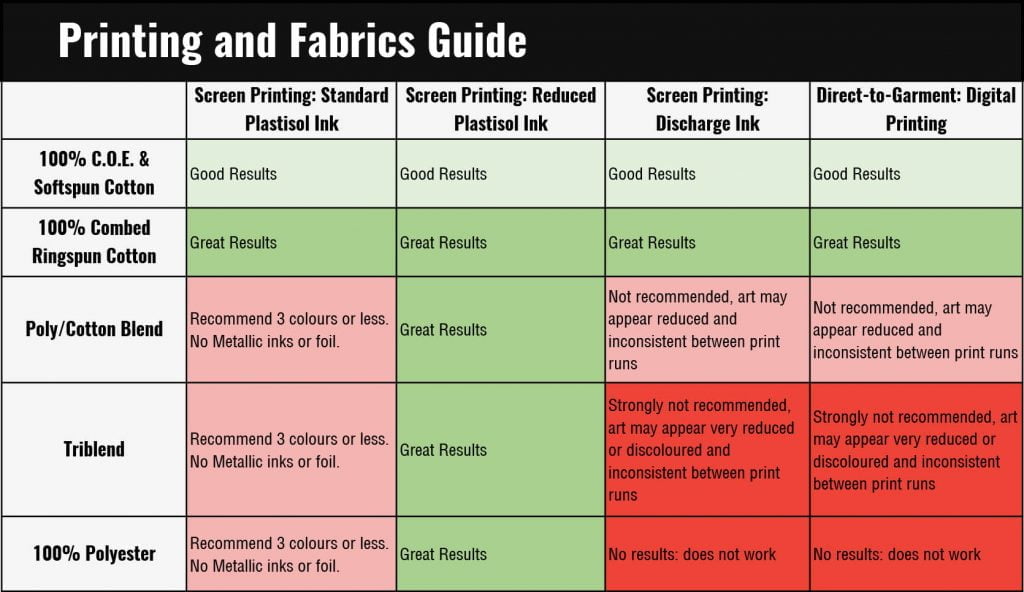

Need a quick overview? Check out our handy Printing and Fabrics Guide below.