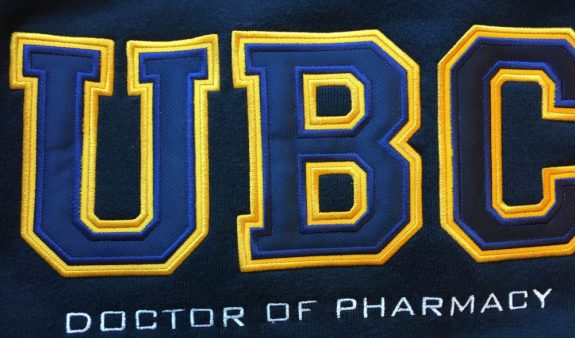

GetBold is the Applique Expert

We know the ins and outs of Applique, which is the process of sewing fabric into a garment. This is most often used for applying university lettering onto sweatshirts and is commonly seen on university or college hoodies. Because it is time-consuming, complex and difficult, many shops don’t do it. We do because we think it’s cool! For this process, you should keep the design relatively simple. Lettering, and block areas of colour work well. Avoid illustrative artwork.

Developing a Design for Applique

Creating a design for the applique process involves cutting pieces of fabric on our in house laser cutter. We can cut up to three layers a a time for perfect accuracy.

The applique pieces are then applied to the garment using a computer programmed embroidery machine that makes sure the stitches go in exactly the right places relative to the cut fabric.

The Advantages of Applique

- Applique allows for the creation of radically different textures and effects and covers larger areas with fewer stitches.

- Some designs benefit from adding a different texture or effect, and for some designs, using an applique might be faster than using conventional fill techniques.

- Applique can be a way of avoiding adding bulk to already thick fabrics.

The Disadvantages of Applique

- Applique can be time-consuming. For some designs, the process can add a significant amount of time and costs to the job. Depending upon the design, it is not always true that the applique process is faster or more efficient than filling in an area with stitches.

- Depending on the number of layers of fabric in an applique, and how thick the backing needs to be on the particular garment, an applique can be quite stiff.

Ultimately some fraying and stray threads can end up happening.

Know What You’re Getting Into

Your embroiderer must know all of the associated costs. From the design, pattern development, dies (if required), the cost of cutting, and the material costs, to the extra time that may be required. You need to know upfront what you’re getting into.

Applique Designs Are Edgy

You may want part of the design effect to be the look of the edge of the applique. There are “fused edge appliques” and a “frayed edge appliques.” They both fall into the “raw edge applique” category and they are both considered relatively easy to do. The “fused edge applique” requires the material to be cut on a laser cutter so that the edges are melted and not likely to fray. For this, the material used in the applique needs to be polyester. The most popular is polyester twill, sometimes know as tackle twill. Also polyester felt is a good choice. With “frayed edge applique” a raw edge of any material becomes a positive because the desired effect is to have a frayed edge.

Sometimes your design looks best without seeing the edges of the applique material. To cover the edges completely you would use a satin stitch, which is a column stitch that cover the cut edges of the cut fabric with stitches that go side to side, but very close together.

The Addition of an Applique

As a decorative surface design technique, applique adds dimension and texture to a fabric or garment. Derived from the French word “appliquer” or Latin word “applicare” it means to join or attach. Possibly originally intended for patchwork, it has since developed into a creative art-form. If you’d like to learn more, talk to us at GetBold, we like a challenge.